Automatic Aerosol Filling And Capping Machine

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Transportation: | Ocean |

| Port: | Shanghai,Ningbo,Lianyungang |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Transportation: | Ocean |

| Port: | Shanghai,Ningbo,Lianyungang |

Model No.: Q-EY-4000P

Brand: Fuda

| Selling Units | : | Set/Sets |

The file is encrypted. Please fill in the following information to continue accessing it

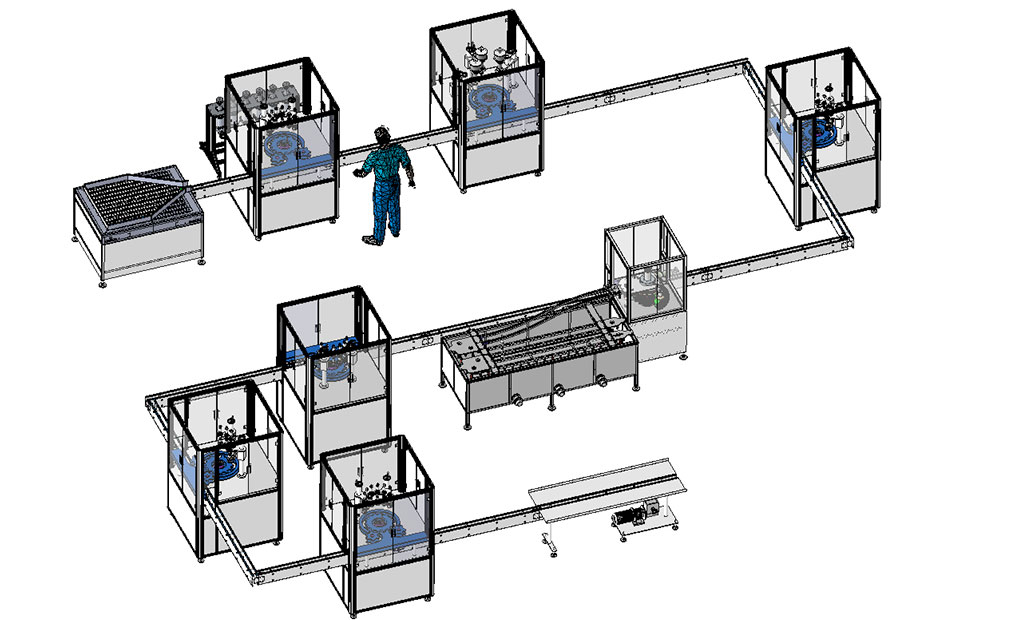

Fully Automatic Aerosol Production is a cutting-edge system designed to streamline the production of aerosol products. This automated solution is capable of efficiently and accurately performing various production processes, including filling, sealing, and labeling aerosol cans.

The system is equipped with advanced technology and intelligent controls to ensure precise and consistent product manufacturing. It can handle a wide range of aerosol products, such as air fresheners, insecticides, and personal care items.

The production system includes various components such as a can feeding system, filling machine, valve inserting machine, crimping machine, propellant filling machine, and a sealing machine. These components work together seamlessly to automate the entire aerosol production process.

The can feeding system efficiently feeds empty cans into the production line, ensuring a continuous supply of cans for filling. The filling machine accurately fills the cans with the desired product, while the valve inserting machine inserts the valves into the cans.

The crimping machine securely crimps the cans, ensuring a tight seal. The propellant filling machine accurately fills the cans with the required propellant, while the sealing machine tightly seals the cans, preventing leakage.

The filling process is carried out with high-speed accuracy, ensuring that each can is filled to the desired level. The sealing mechanism securely seals the cans to prevent leakage and maintain product integrity.Our company also has other productions including Automatic Aerosol Filling Machines、Semi-Automatic Aerosol Filling Machines、Measurement Instruments.

· Modular design meeting customers’ different requirements

· PLC system, intelligent and convenient

· Multiple alarming systems to ensure safe operation

· 3 dosing moves at one time

· Different layouts “Straight”, “L”, and “U” optional

| Outline (L*W*H) | Capacity | Liquid Filling Volume | Gas Filling Volume | Accuracy |

| 22000*1500*2000mm | 30~45 cans/minute | 50~550ml | 0~0.6Mpa | ≤ ±1g |

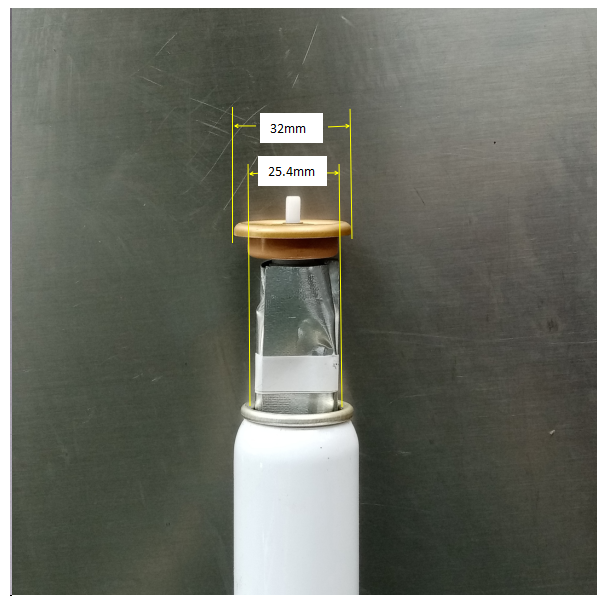

| Applicable Can Diameter | Applicable Can Height | Applicable Valve Size | Working Air Pressure | Maximum Air Consumption |

| 40~66mm | 80~330mm | 1 Inch | 0.7~0.8Mpa(102~116Psi) | 4000L/M |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.