Aerosol Filling Machines Buy

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Transportation: | Ocean |

| Port: | Shanghai,Ningbo,Lianyungang |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Transportation: | Ocean |

| Port: | Shanghai,Ningbo,Lianyungang |

Model No.: Q-EY-4000P

Brand: Fuda

| Selling Units | : | Set/Sets |

The file is encrypted. Please fill in the following information to continue accessing it

Aerosol filling machines are industrial machines used to fill aerosol products, such as sprays, foams, and mists, into aerosol cans or containers. These machines are designed to automate the filling process and ensure accurate and consistent filling of the products.

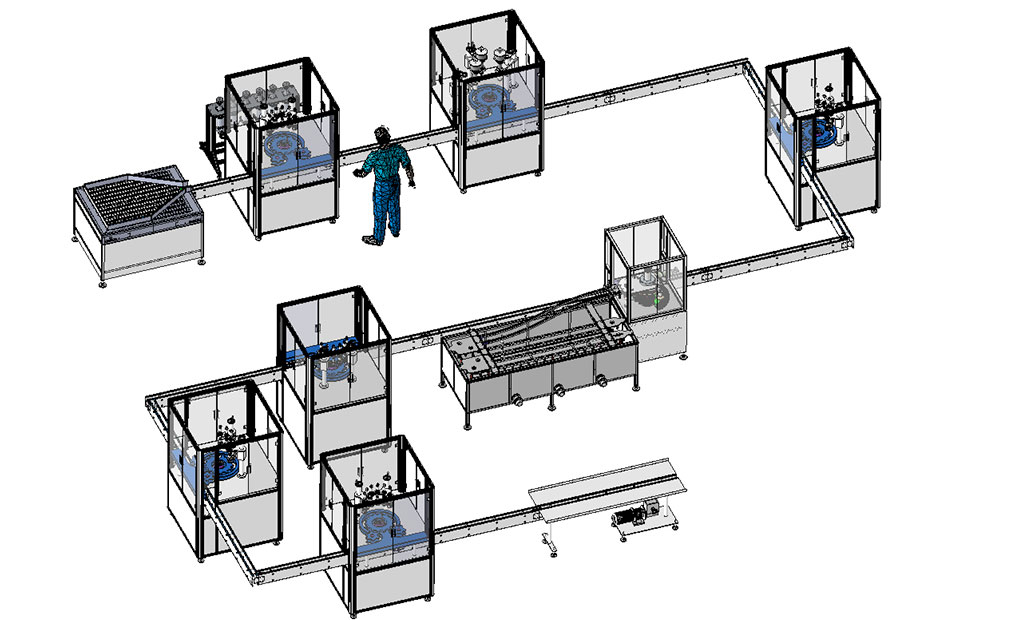

Aerosol filling machines typically consist of several components, including a can feeding system, a product filling system, a propellant filling system, a valve inserting system, and a sealing system. The can feeding system feeds empty aerosol cans into the machine, while the product filling system fills the cans with the desired product. The propellant filling system then adds the propellant, which is usually a compressed gas, to pressurize the can and enable the product to be dispensed as a spray. The valve inserting system inserts the valve into the can, and the sealing system seals the can to prevent leakage.

These machines can be customized to accommodate different sizes and types of aerosol cans, as well as different product formulations. They can also be equipped with additional features, such as automatic capping, labeling, and coding systems.

Aerosol filling machines are commonly used in industries such as cosmetics, household products, automotive, and pharmaceuticals, where aerosol products are widely used. These machines offer increased efficiency, accuracy, and productivity in the aerosol filling process, reducing manual labor and ensuring product consistency.Our company also has other productions including Automatic Aerosol Filling Machines、Semi-Automatic Aerosol Filling Machines、Measurement Instruments.

· Modular design meeting customers’ different requirements

· PLC system, intelligent and convenient

· Multiple alarming systems to ensure safe operation

· 3 dosing moves at one time

· Different layouts “Straight”, “L”, and “U” optional

| Outline (L*W*H) | Capacity | Liquid Filling Volume | Gas Filling Volume | Accuracy |

| 22000*1500*2000mm | 30~45 cans/minute | 50~550ml | 0~0.6Mpa | ≤ ±1g |

| Applicable Can Diameter | Applicable Can Height | Applicable Valve Size | Working Air Pressure | Maximum Air Consumption |

| 40~66mm | 80~330mm | 1 Inch | 0.7~0.8Mpa(102~116Psi) | 4000L/M |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.